How Solestial Scaled Space-Grade Solar Manufacturing with Automation

THE PROBLEM

Scaling Space-Stable Solar at Lower Production Costs

Solestial is defining the future of space power as a provider of space-stable silicon photovoltaics. Their pioneering solar cells can self-heal from radiation damage, and deliver energy solutions in a flexible, low mass package at one-tenth of the conventional costs.

To realize their ambition of scaling from a one megawatt capacity facility to a 10-megawatt production capacity, Solestial recognized the necessity of moving from building modules completely by hand to utilizing automated equipment.

Additionally, the accelerated pace of production had to be balanced with more accurate simulations to de-risk the investment in automation.

Solestial needed a simulation-first automation platform to rapidly test and bring their ideas to life as well as an automation partner who could think creatively, and solve problems.

![]()

“One thing that our team particularly liked about Vention is their ability to simulate the workflows, to actually test the equipment that they designed before it’s been built. We need Vention’s ecosystem to support us as we move forward with our product development.”—Stan Herasimenka, CTO, Solestial

THE PROJECT

Automating Multiple Custom Processes with Vention’s Platform

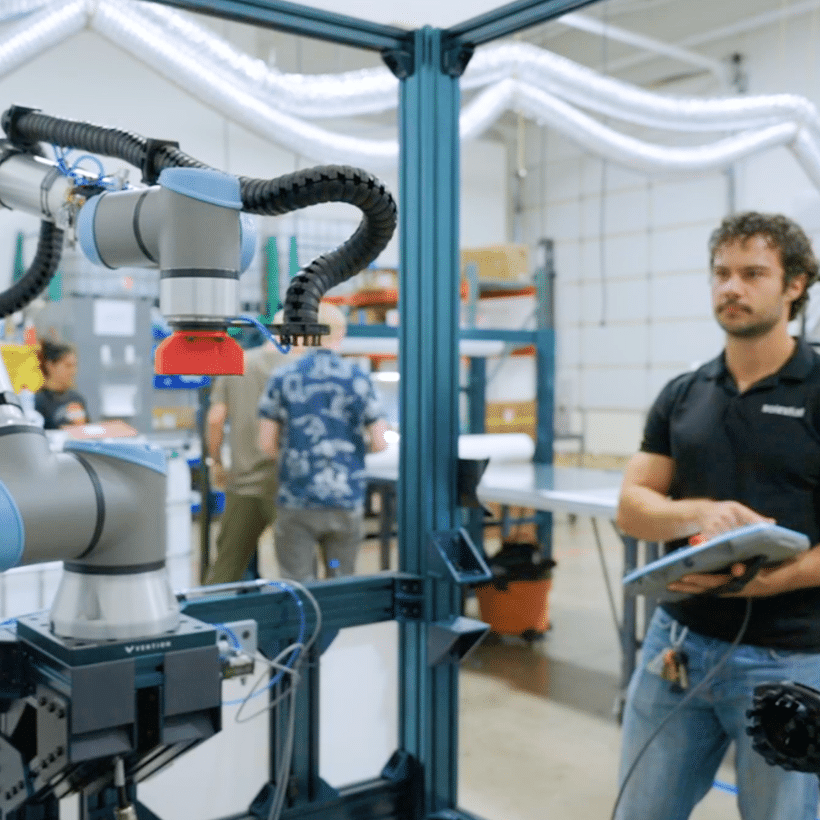

Solestial partnered with Vention to automate key steps in scaling production of its space-grade solar technology. The initial projects included automating wafer loading to increase throughput and reduce breakage, as well as automating wet-etch hoods used for processing wafers.

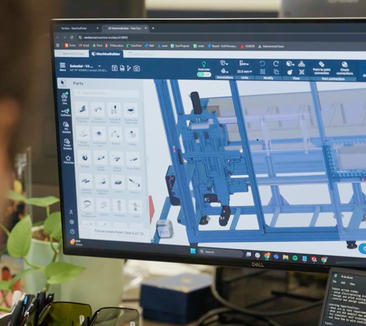

Using Vention’s intuitive MachineBuilder platform, Solestial collaborated closely with Vention engineers to design systems that integrated seamlessly with existing equipment. The digital design environment supported fast iteration, workflow visualization, and motion studies, which helped Solestial validate concepts and estimate throughput before committing to a build.

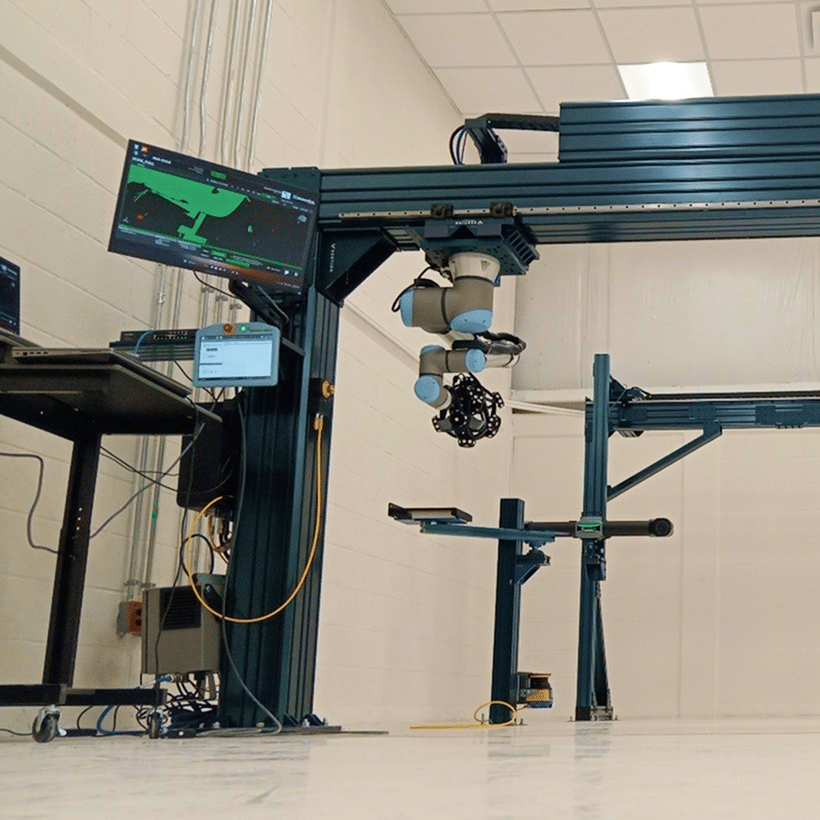

For the wafer-loading cell, Vention delivered a custom gantry system pre-assembled and ready for rapid installation, completing the project in four weeks. Dedicated engineering support helped Solestial deploy a precise pick-and-place solution for delicate wafer handling.

Vention also supported automation of Solestial’s long wet-etch hoods, which contain 12 to 16 tanks each. The team worked together to configure custom actuators and develop specialized enclosures tailored to the process requirements, helping bring a highly customized piece of equipment into automated production.

THE RESULTS

Building the Manufacturing Engine for Next-Generation Space Solar

Solestial’s partnership with Vention has delivered both immediate performance gains and long-term manufacturing advantage. The first key deployment of the automated wafer loading increased throughput by 50% while maintaining the precise handling required for ultra-thin wafers.

Automating with Vention also helped boost the deployment speed across all automation projects. For instance, the custom gantry system was shipped pre-assembled and installed in four weeks, helping Solestial scale production quickly to meet growing demand.

As Solestial expands its manufacturing capacity, automation is being evaluated through a long-term ROI lens. With Vention’s digital platform and simulation-first approach, Solestial can validate designs before purchasing equipment, enabling smarter capital planning and faster time to production.

Looking ahead, Vention’s collaborative engineering support, rapid design iteration, and hands-on deployment expertise will help Solestial bring new production processes online efficiently and build the manufacturing foundation required for large-scale, space-solar production.