A Supply Chain Hero: Tanya Lance Drives Smarter Supply Chain Strategies at SPM

Our Supply Chain Heroes program recognizes and celebrates the hard work of LeanDNA customers who optimize inventory, reduce shortages, and empower their companies to operate more efficiently. Every hero has a story, and we’re here to tell them.

For Tanya Lance, Materials Manager at Special Products & MFG (SPM), driving efficiency and innovation has always been about finding better ways to empower her team. In the fast-paced world of precision manufacturing, she recognized that the company’s existing tools were creating more complexity than clarity.

Tackling Challenges Head-On

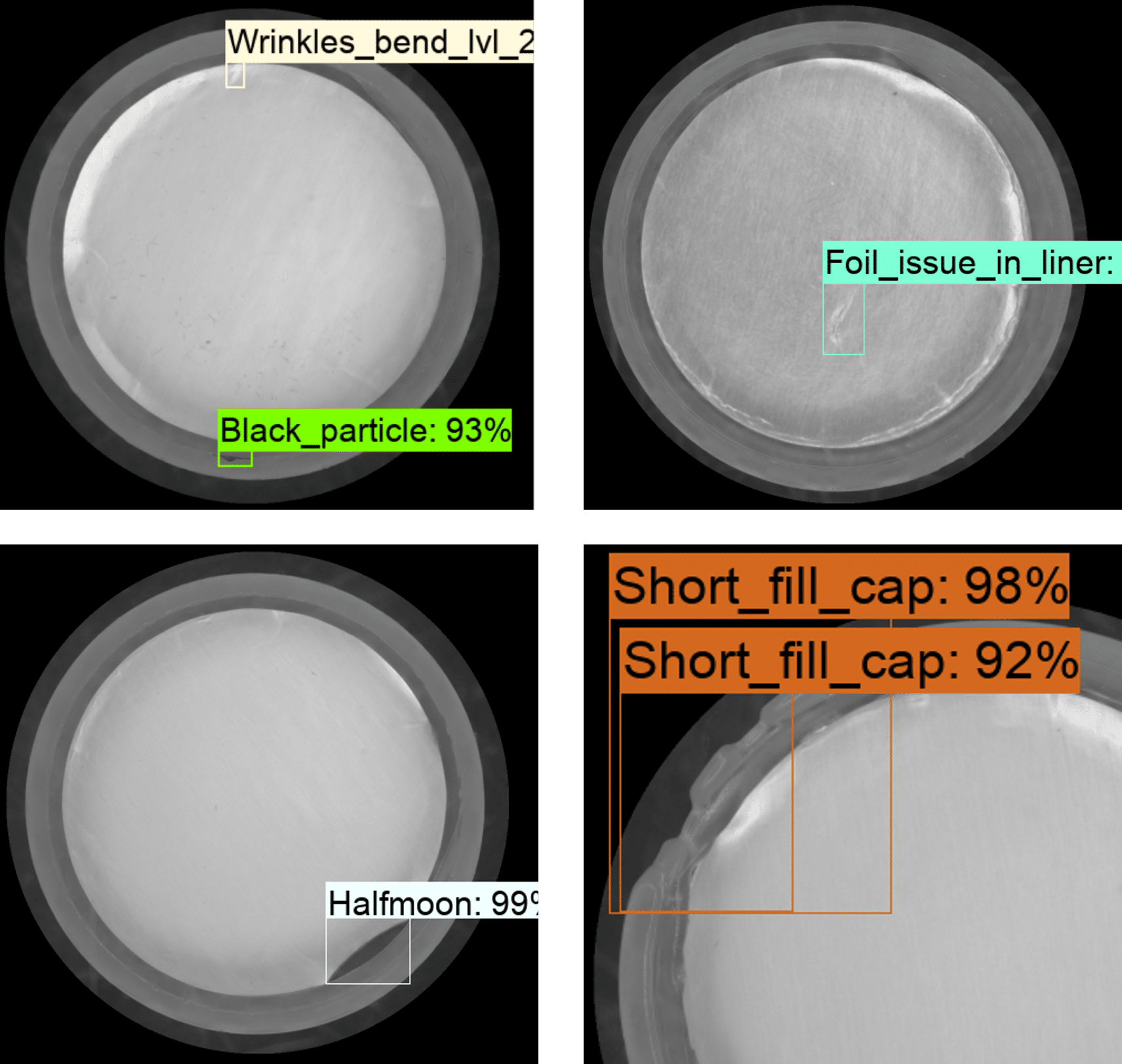

The team’s ERP system generated massive amounts of data, but translating that into actionable insights was a challenge. Buyers relied on ERP reports, spreadsheets, and supplier feedback. These methods lacked consistency and failed to account for different commodity types that required unique buying strategies. Without reliable visibility into metrics like min/max levels or supplier performance, the team was stuck in reactive execution rather than proactive improvement.

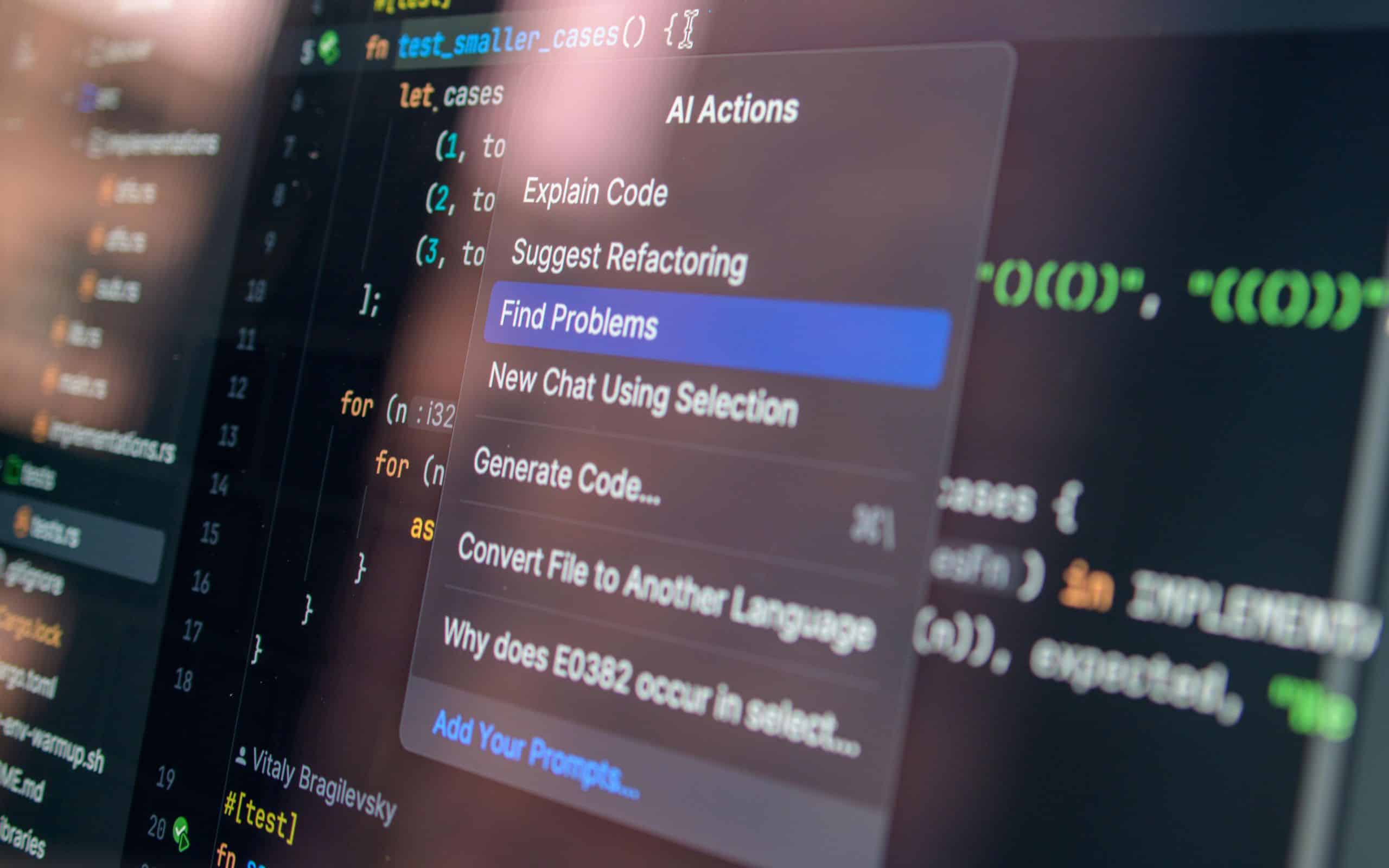

Before LeanDNA, Tanya and the team tried to bridge these gaps by developing custom SQL and PowerBI dashboards. While helpful in the short term, these tools required significant internal resources to maintain and rebuild for each new analysis. Lacking AI-driven insights, the team couldn’t proactively identify operational improvements.

Shifting to a Smarter Solution

Recognizing the need for a smarter approach, Tanya and the team chose to implement LeanDNA and quickly began to see measurable results.

“We can now identify potential shortages well in advance, enabling smarter purchasing decisions and better resource planning.” -Tanya Lance, Materials Manager at SPM

SPM saw improvements in Clear-to-build percentages and PO confirmations, and min/max inventory management became far more accurate. More importantly, the team had clearly defined, actionable tasks that free them from constant firefighting.

“In recent months, we have reduced shortages, improved supplier on-time delivery, and reallocated buyer time toward strategic initiatives. These improvements have not only enhanced day-to-day efficiency but also created opportunities to focus more on cost savings and supplier development.”

Building Toward the Future

Tanya and the SPM team are already looking to the future. Their next priority is leveraging LeanDNA’s AI-driven min/max recommendations to further refine inventory strategies. They plan to start comparing current min/max settings with LeanDNA-generated insights and factoring in practical considerations like lot sizing, skid quantities, and minimum order values. They are working toward a balanced approach that improves inventory accuracy without compromising on-time delivery or inventory turns.

For Tanya, the journey has reinforced one key lesson:

“One of the most valuable lessons we’ve learned is that solving supply chain challenges doesn’t always require additional headcount. It requires smarter processes and better tools.”

By directing her buyers toward actionable tasks through LeanDNA, Tanya has created opportunities for cross-training, cost reduction initiatives, and more meaningful supplier performance conversations. This shift has allowed her team to move beyond reactive PO follow-up and focus on activities that drive long-term success.

A Tip From the Hero

When asked what she would share with other supply chain leaders, Tanya points to the importance of embracing intelligent solutions.

“Intelligent supply chain solutions like LeanDNA, with built-in AI analysis, elevate procurement beyond simply supplying materials; they enable proactive, strategic decision-making.”

Through her vision and leadership, Tanya has turned challenges into opportunities for SPM. By championing LeanDNA and shifting her team toward proactive, value-added work, she’s demonstrating how one supply chain leader can create lasting impact, not only for her team, but for suppliers and customers alike.